The 2-Minute Rule for Safety Network

Table of ContentsAll about Safety NetworkSafety Network for BeginnersMore About Safety NetworkWhat Does Safety Network Mean?

Since the controllers are full website traffic activated, it is feasible for stages to be avoided. The selection of circulation lines and also arrows on the diagram represents all feasible sequence courses the controller unit can take (https://www.awwwards.com/s4fetynetw0rk/). The different series variations received Figures 7-6 and 7-7 apply as well as depend on the website traffic patterns at the interchange.

A duplicate of the controller's information can be stored in a main data source, customized, as well as downloaded to the controller in entire or partially. Implementation of downloaded and install interval periods and also phase series may undergo neighborhood minimums, optimums, or other checks, or the downloaded and install information might overwrite existing data with no checks.

Maximum dimensions are specified for the controller, a producer is free to make a device of any type of smaller sized dimension from any product, in any kind of form, with internal sub-components of any kind of type, as long as it meets the other requirements of the criterion. There are no needs that allow interchangeability of sub-components or software between controllers from different manufacturers.

The smart Trick of Safety Network That Nobody is Discussing

One includes binary (on or off) reasoning cables (analog) attached to the controller using 3 round connectors assigned as MS-A, MS-B, and MS-C. This interface was originally standard in a previous NEMA standard - TS 1. It is still extensively used, and also continues to be an option within TS 2. It prevails for NEMA-compliant controllers to provide additional input/ result control cords by means of a non-standard connector MS-D.

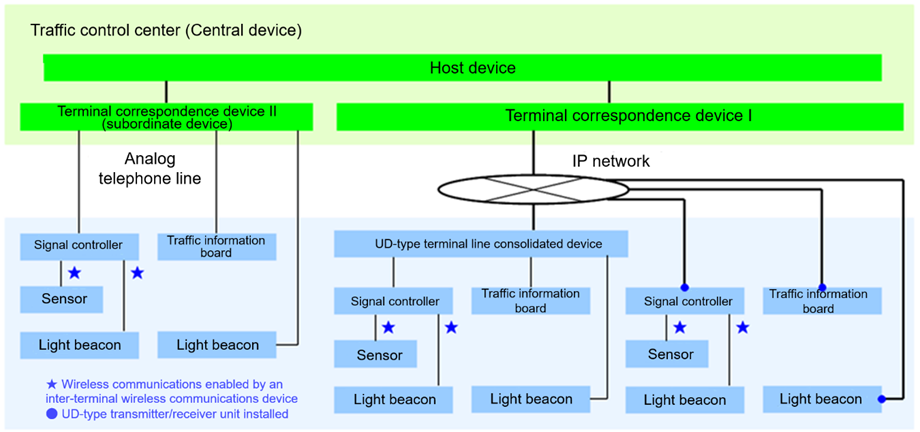

This option decreases the amount of circuitry in the closet by giving an analog-to-digital converter as well as collector near to the detectors or load switches that are the source or destination of the inputs or outputs. An easy serial interactions wire links these bus interface units to the controller. https://www.quora.com/profile/Gloria-Johnson-475. Each bus interface device sustains numerous detectors or tons switches.

It is planned to operate in a "NEMA" cabinet satisfying the NEMA TS 2 requirements, and also can use either the A, B, C connectors (typically called read review the TS 1 interface), or serial bus interface (usually called the TS 2 serial user interface) for closet inputs and outputs. For activated website traffic signal controllers, the TS 2 requirement defines performance, primarily in the following areas: Stages set up in a certain series in rings with obstacles Overlaps (environment-friendly results that can span multiple stages) Single as well as twin access logic (what phase to select in the 2nd ring if no phone call there) Pedestrian reuse (enabling pedestrian Stroll to start aside from at the beginning of eco-friendly) Phase intervals as well as their timing (including minimum as well as maximum eco-friendly times, yellow clearance, red clearance, as well as pedestrian timing) Sychronisation timing (cycle, offset, split, permissive duration, time base) Phase selection factors (when "stage following" is picked) Phase phone call storage space (locking telephone calls) User-specified automobile as well as pedestrian recalls Automatic recall at forced phase discontinuation Conditional re-service of a phase within a barrier group Synchronised space out Begin up process Red return time Preemption Flashing procedure, dimming, diagnostics Remote interactions (consisting of NTCIP demands) The exact same performance relates to NEMA controllers making use of either of the cabinet input/ result user interfaces (A, B, C adapters or serial bus).

Everything about Safety Network

Any individual can develop software application for an ATC controller, for any type of objective (e. g., traffic signal control, field master unit, ramp metering, count stations, vibrant message sign control, reversible lane control, and so on) recognizing that it will operate controllers from any type of manufacturer. A lot of ATC controller software application for traffic signals follows the performance defined in NEMA TS 2, and is functionally similar to a NEMA controller.

The TS 1 cupboard input/ result interface module includes a standardized fourth port, called the D adapter. The ITS Closet requirement (10) incorporates the very best attributes of the Caltrans Model 33x cabinet as well as the NEMA TS 2 serial cupboard, while offering extra inputs as well as outputs, even more dispersed as well as adaptable fault tracking, and minimized cupboard circuitry (Traffic control companies).

This protocol is the same as utilized inside in the ATC 2070. It is a brand-new criterion as well as it will certainly take some time before compliant components are readily offered and also great deals of ITS closets are deployed. ATC 2070 controller software requires some modification to operate in an ITS Cupboard.

These standards cover the equipment for closets and also all parts, including the controller. The Version 170 controller is based on the Motorola 6800 processor, which is no much longer manufactured.

The Safety Network PDFs

The Model 170 controller is commonly made use of as well as will certainly remain to be utilized for time to find. As substitute components are no longer produced for some parts, they will have to become replaced. Caltrans created the Model 2070 controller as its replacement. The Design 33x closets utilized with the Version 170 controller are supported by an optional Model 170 style field input/ outcome module in the ATC 2070 common, and it is consequently relatively very easy to change a Version 170 controller with an ATC 2070.